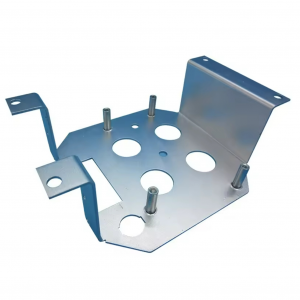

Musamman madaidaicin sashi bakin karfe takardar karfe stamping sassa

Bayani

| Nau'in Samfur | samfur na musamman | |||||||||||

| Sabis Tasha Daya | Ci gaban ƙira da ƙira-ƙaddamar da samfurori-samfurin samarwa-duba-duba-jiyya-fasa-bayarwa. | |||||||||||

| Tsari | stamping, lankwasawa, zurfin zane, sheet karfe ƙirƙira, walda, Laser sabon da dai sauransu. | |||||||||||

| Kayayyaki | carbon karfe, bakin karfe, aluminum, jan karfe, galvanized karfe da dai sauransu | |||||||||||

| Girma | bisa ga zane-zane ko samfurori na abokin ciniki. | |||||||||||

| Gama | Fesa zanen, electroplating, zafi tsoma galvanizing, foda shafi, electrophoresis, anodizing, blackening, da dai sauransu. | |||||||||||

| Yankin Aikace-aikace | Sassan motoci, sassan injinan noma, sassan injin injiniya, sassan injiniyan gini, kayan aikin lambu, sassan injinan muhalli, sassan jirgi, sassan jirgin sama, kayan aikin bututu, sassan kayan aikin kayan aiki, sassan kayan wasan yara, sassan lantarki, da sauransu. | |||||||||||

Abubuwan iyawa

Domin biyan bukatun abokin ciniki, Xinzhe yana ba da cikakken sabis a cikin ɗakin kayan aiki na gida don ƙira, injiniyanci, da kuma samar da nau'ikan nau'ikan stamping na ƙarfe ya mutu, gami da fili, ci gaba, zane, da kayan aikin samfuri.

Mafi mahimmanci, kayan aikin mu na tattalin arziki, kayan aikin hatimin ƙarfe masu inganci suna rage samarwa da kashe kuɗin aiki. Don tsawon lokacin ayyukan tambari, muna kuma kulawa da gyara duk mutuwar abokan cinikinmu ba tare da ƙarin kuɗi ba.

1.Quick kayan aiki gyare-gyare don lissafin canje-canje a aikin injiniya.

2. Mafi kyawun kayan aiki.

3. ƙwarewa a ƙirar kayan aiki.

4. ƙwararrun ƙwararrun injiniyoyi da ƙwararrun kayan aiki waɗanda ke da ingantaccen ilimin tambari.

5. Yin amfani da Advanced Wire EDM, za ku iya daidai da araha yanke sassan ku.

Gudanar da inganci

Vickers taurin kayan aiki.

Kayan auna bayanan martaba.

Spectrograph kayan aiki.

Kayan aiki guda uku.

Hoton jigilar kaya

Tsarin samarwa

01. Mold zane

02. Gyaran Mold

03. sarrafa yankan waya

04. Maganin zafi na Mold

05. Mold taro

06. Mold gyara kurakurai

07. Zazzagewa

08. lantarki

09. Gwajin Samfura

10. Kunshin

Electrophoresis tsari

Tsarin electrophoresis ya ƙunshi matakai masu zuwa:

1. Samfurin sarrafawa: Zaɓi hanyar haɓaka samfurin da ta dace kuma aiwatar da matakan pretreatment masu dacewa bisa ga nau'in samfurin, kamar rushewar tantanin halitta, solubilization na furotin, da sauransu.

2. Shirye-shiryen buffer: Buffer yana taka rawa wajen kiyaye kwanciyar hankali na pH, samar da haɓakar ionic da samfuran diluting yayin gwaje-gwajen electrophoresis. Lokacin shirya buffers, reagents suna buƙatar auna su daidai kuma a shafe su daidai gwargwado.

3. Shirye-shiryen tankin electrophoresis da na'urorin lantarki: Tsaftace tankin electrophoresis da na'urorin lantarki don tabbatar da cewa babu wani datti da ya rage. Bincika cewa na'urorin lantarki suna cikin kusanci da bangon tanki kuma cewa layin haɗin ba su karye ko gajeriyar kewayawa ba.

4. Shirya fenti: Narkar da fentin electrophoretic a cikin ruwa don samar da daidaituwa da tsayayyen dakatarwa. A abun da ke ciki na shafi ya kamata a zaba bisa ga bukatun na workpiece da aikace-aikace filin, kuma yawanci ya hada da guduro, sauran ƙarfi, curing wakili, filler, da dai sauransu Bugu da kari, wasu Additives kamar defoaming jamiái da leveling jamiái za a iya kara.

5. Saita tankin electrophoresis: Sanya tankin electrophoresis wanda ke dauke da fenti a cikin kayan aikin electrophoresis, kuma haɗa na'urori masu inganci da mara kyau zuwa wutar lantarki. An haɗa madaidaicin lantarki zuwa farantin karfe a cikin tanki na electrophoresis, kuma ana haɗa wutar lantarki mara kyau zuwa aikin aiki don samar da filin lantarki a ƙarƙashin aikin ƙarfin lantarki.

6. Daidaita sigogi na fenti: Dangane da buƙatun kayan aiki da fenti, daidaita sigogin fenti a cikin tankin electrophoresis, kamar maida hankali, ƙimar pH, zazzabi da ƙarfin lantarki, da sauransu.

7. Samfurin lodi: Ƙara abun da za a gwada a cikin tanki na electrophoresis da aka shirya don rabuwa. Lokacin ɗora samfurori, ya kamata a kula da shi don kauce wa iska ta shiga gel don kauce wa rinjayar tasirin rabuwa. Ƙayyade adadin nauyin da ya dace dangane da girman samfurin da maida hankali. Da yawa ko kaɗan na iya shafar sakamakon gwaji.

8. Fara electrophoresis: Sanya kayan aikin da aka sarrafa a cikin tanki na electrophoresis kuma tabbatar da cewa aikin yana cikin cikakkiyar lamba tare da fenti. Kunna wutar lantarki, yana haifar da cajin barbashi ko ions a cikin fenti don matsawa zuwa da ajiyewa a saman kayan aikin ƙarƙashin aikin filin lantarki.

9. Shafi curing: Bayan surface shafi na workpiece kai da ake bukata kauri, dauki workpiece daga cikin electrophoresis tank da aika shi zuwa ga tanda ko iska bushe don ƙarfafa shafi.

Abubuwan da ke sama sune gabaɗayan matakan tsarin electrophoresis. Ana iya daidaita takamaiman ayyuka saboda kayan aiki da matakai daban-daban. Yayin duk aikin electrophoresis, sigogi daban-daban da matakan aiki suna buƙatar kulawa sosai don tabbatar da ingancin samfur da kwanciyar hankali.

HIDIMARMU

1. Ƙwararren R&D: Don taimakawa kasuwancin ku, injiniyoyinmu suna ƙirƙirar sabbin kayayyaki don abubuwanku.

2. Ƙwararrun Ƙwararrun Ƙwararrun Ƙirar: Kowane samfurin ana duba shi sosai don tabbatar da yana aiki da kyau kafin a tura shi.

3. Ƙwararrun ma'aikatan dabaru - tattarawa na keɓaɓɓu da saurin sa ido suna ba da garantin amincin samfurin har sai ya isa gare ku.

4. Ma'aikatan siyayyar da ke tattare da kai wanda ke ba abokan ciniki da sauri, taimakon kwararru a kowane lokaci.

5.A ƙwararrun ma'aikatan tallace-tallace za su ba da mafi kyawun ilimin ƙwararru don ba ku damar gudanar da kamfani tare da abokan ciniki yadda ya kamata.