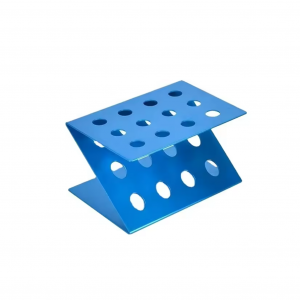

Musamman madaidaicin ɓangarorin lankwasa motoci na ƙarfe

Bayani

| Nau'in Samfur | samfur na musamman | |||||||||||

| Sabis Tasha Daya | Ci gaban ƙira da ƙira-ƙaddamar da samfurori-samfurin samarwa-duba-duba-jiyya-fasa-bayarwa. | |||||||||||

| Tsari | stamping, lankwasawa, zurfin zane, sheet karfe ƙirƙira, walda, Laser sabon da dai sauransu. | |||||||||||

| Kayayyaki | carbon karfe, bakin karfe, aluminum, jan karfe, galvanized karfe da dai sauransu | |||||||||||

| Girma | bisa ga zane-zane ko samfurori na abokin ciniki. | |||||||||||

| Gama | Fesa zanen, electroplating, zafi tsoma galvanizing, foda shafi, electrophoresis, anodizing, blackening, da dai sauransu. | |||||||||||

| Yankin Aikace-aikace | Sassan motoci, sassan injinan noma, sassan injin injiniya, sassan injiniyan gini, kayan aikin lambu, sassan injinan muhalli, sassan jirgi, sassan jirgin sama, kayan aikin bututu, sassan kayan aikin kayan aiki, sassan kayan wasan yara, sassan lantarki, da sauransu. | |||||||||||

Ƙa'idar lankwasawa

Ka'idar lankwasa ƙarfe ya ƙunshi nakasar filastik na kayan ƙarfe a ƙarƙashin aikin sojojin waje. Mai zuwa shine cikakken gabatarwa:

A lokacin aikin lanƙwasawa, takardar ƙarfe ta farko ta sami nakasar roba sannan ta shiga nakasar filastik. A cikin mataki na farko na lankwasawa filastik, takardar tana lanƙwasa kyauta. Yayin da matsin lamba da mold ke yi akan farantin yana ƙaruwa, tuntuɓar da ke tsakanin farantin da gyare-gyaren a hankali ya zama kusa, kuma radius na curvature da lanƙwasa hannun lokacin yana raguwa.

A lokacin aikin lanƙwasawa, ma'aunin damuwa yana jurewa nakasar roba, yayin da nakasar filastik ke faruwa a bangarorin biyu na wurin lanƙwasawa, yana haifar da canje-canje mai girma a cikin kayan ƙarfe.

Don guje wa ɓarna, ɓarna da sauran matsaloli a wurin lanƙwasawa, ana yin gyare-gyare sau da yawa ta hanyar ƙara radius na lanƙwasa, lanƙwasa sau da yawa, da dai sauransu.

Wannan ka'ida ta shafi ba kawai ga lanƙwasa kayan lebur ba, har ma da lanƙwasa bututun ƙarfe, kamar a cikin injin ɗin lankwasa bututun hydraulic inda ake amfani da matsin lamba da tsarin hydraulic ya haifar don siffata bututu. Gabaɗaya, lanƙwasa ƙarfe hanya ce ta sarrafawa wacce ke amfani da nakasar filastik na ƙarfe don kera sassa ko sassa na siffar da girman da ake so.

Gudanar da inganci

Vickers taurin kayan aiki.

Kayan auna bayanan martaba.

Spectrograph kayan aiki.

Kayan aiki guda uku.

Hoton jigilar kaya

Tsarin samarwa

01. Mold zane

02. Gyaran Mold

03. sarrafa yankan waya

04. Maganin zafi na Mold

05. Mold taro

06. Mold gyara kurakurai

07. Zazzagewa

08. lantarki

09. Gwajin Samfura

10. Kunshin

zabin kayan abu

Daban-daban kayan sun dace da matakai daban-daban na lankwasawa. Zaɓin kayan yana buƙatar dogara akan buƙatun samfur da buƙatun sarrafawa. Gabaɗaya, ana buƙatar zaɓin kayan da ke da inganci mai kyau da ingantaccen aiki.

1. Kayan ƙarfe: Ya dace da sassa tare da ƙananan kusurwoyi masu lankwasa, siffofi masu sauƙi da ƙananan buƙatu, kamar allon nuni, ɗakunan katako, ɗakunan ajiya da sauran kayan aiki.

2. Aluminum: Yana da abũbuwan amfãni daga haske nauyi, high ƙarfi, lalata juriya da kuma conductivity. Ya dace da sassan da ke buƙatar babban madaidaici da manyan kusurwoyi, kamar chassis, firam, sassa, da sauransu.

3. Bakin karfe: Yana da kyakkyawan juriya na lalata, babban ƙarfi, mai kyau tauri da sauran halaye, amma yana da wuyar aiwatarwa. Ya dace da ɓangarorin da ke buƙatar babban madaidaici, kamar masana'antar sinadarai, kayan aikin likita, da sauransu.

Me ya sa za a zabi Xinzhe ga al'ada karfe stamping sassa?

Lokacin da kuka zo Xinzhe, za ku zo wurin ƙwararrun ƙwararrun tambarin ƙarfe. Mun mayar da hankali a kan karfe stamping fiye da shekaru 10, bauta wa abokan ciniki daga ko'ina cikin duniya. ƙwararrun ƙwararrun injiniyoyinmu da ƙwararrun ƙwararrun ƙwararru ne kuma kwazo.

Menene sirrin nasarar mu? Amsar ita ce kalmomi guda biyu: ƙayyadaddun bayanai da tabbatar da inganci. Kowane aiki na musamman ne a gare mu. Ganin ku yana ba da ƙarfi, kuma alhakinmu ne mu tabbatar da wannan hangen nesa. Muna yin haka ta ƙoƙarin fahimtar kowane ɗan dalla-dalla na aikin ku.

Da zarar mun san ra'ayin ku, za mu yi aiki don samar da shi. Akwai wuraren bincike da yawa a duk tsawon aikin. Wannan yana ba mu damar tabbatar da cewa samfurin ƙarshe ya cika buƙatun ku daidai.

A halin yanzu, ƙungiyarmu ta ƙware a sabis na tambarin ƙarfe na al'ada a wurare masu zuwa:

Tambarin ci gaba don ƙanana da manyan batches

Karamin tsari na sakandare stamping

Taɓa cikin-gyara

Sakandare/taɓawar taro

Ƙirƙira da machining