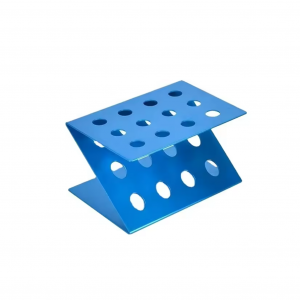

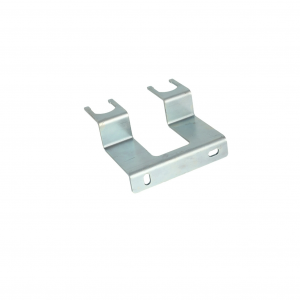

daidai sanyi stamping tsari maroki

Bayani

| Nau'in Samfur | samfur na musamman | |||||||||||

| Sabis Tasha Daya | Ci gaban ƙira da ƙira-ƙaddamar da samfurori-samfurin samarwa-duba-duba-jiyya-fasa-bayarwa. | |||||||||||

| Tsari | stamping, lankwasawa, zurfin zane, sheet karfe ƙirƙira, walda, Laser sabon da dai sauransu. | |||||||||||

| Kayayyaki | carbon karfe, bakin karfe, aluminum, jan karfe, galvanized karfe da dai sauransu | |||||||||||

| Girma | bisa ga zane-zane ko samfurori na abokin ciniki. | |||||||||||

| Gama | Fesa zanen, electroplating, zafi tsoma galvanizing, foda shafi, electrophoresis, anodizing, blackening, da dai sauransu. | |||||||||||

| Yankin Aikace-aikace | Sassan motoci, sassan injinan noma, sassan injin injiniya, sassan injiniyan gini, kayan aikin lambu, sassan injinan muhalli, sassan jirgi, sassan jirgin sama, kayan aikin bututu, sassan kayan aikin kayan aiki, sassan kayan wasan yara, sassan lantarki, da sauransu. | |||||||||||

Abvantbuwan amfãni

1. Fiye da shekaru 10na ƙwararrun kasuwancin ƙasashen waje.

2. Samar dasabis na tsayawa ɗayadaga ƙirar ƙira zuwa isar da samfur.

3. Fast bayarwa lokaci, game da30-40 kwanaki. A stock cikin mako guda.

4. Tsananin kula da inganci da sarrafa tsari (ISOƙwararrun masana'anta da masana'anta).

5. More m farashin.

6. Professional, mu factory yana dafiye da 10shekaru na tarihi a filin karfe stamping sheet karfe.

Gudanar da inganci

Vickers taurin kayan aiki.

Kayan auna bayanan martaba.

Spectrograph kayan aiki.

Kayan aiki guda uku.

Hoton jigilar kaya

Tsarin samarwa

01. Mold zane

02. Gyaran Mold

03. sarrafa yankan waya

04. Maganin zafi na Mold

05. Mold taro

06. Mold gyara kurakurai

07. Zazzagewa

08. lantarki

09. Gwajin Samfura

10. Kunshin

Tushen hatimi

Yin tambari (wanda kuma ake kira latsawa) ya ƙunshi sanya ƙarfe mai lebur a cikin coil ko babu komai cikin na'ura mai tambari. A cikin latsawa, kayan aiki da saman saman mutun suna siffanta ƙarfe zuwa siffar da ake so. Duka, barranta, lankwasawa, tambari, ƙwaƙƙwara da flanging duk dabarun yin tambari ne da ake amfani da su wajen siffata ƙarfe.

Kafin a iya samar da kayan, ƙwararrun ƙwararru dole ne su tsara ƙirar ta hanyar injiniyan CAD/CAM. Waɗannan ƙirar dole ne su kasance daidai gwargwadon yuwuwar don tabbatar da tsaftataccen tsafta ga kowane naushi da lanƙwasa don ingantaccen sashi. Samfurin 3D na kayan aiki guda ɗaya zai iya ƙunsar ɗaruruwan sassa, don haka tsarin ƙirar galibi yana da rikitarwa kuma yana ɗaukar lokaci.

Da zarar an ƙaddara ƙirar kayan aiki, masana'antun za su iya amfani da injina iri-iri, niƙa, yanke waya, da sauran ayyukan masana'anta don kammala samarwa.

Karfe stamping tsari zane

Tambarin ƙarfe wani tsari ne mai sarƙaƙƙiya wanda zai iya haɗawa da hanyoyin samar da ƙarfe iri-iri - ɓarna, naushi, lankwasa da naushi, da sauransu.

Blanking: Wannan tsari ya ƙunshi yanke mugun zance ko siffar samfur. Manufar wannan mataki shine ragewa da guje wa burrs, wanda zai iya ƙara farashin ɓangaren kuma ƙara lokacin bayarwa. Wannan mataki shine don tantance diamita na ramin, lissafi/taper, tazarar gefen ramin da kuma inda za'a saka naushi na farko.

Lankwasawa: Lokacin zana lanƙwasa a cikin sassan ƙarfe da aka hatimi, yana da mahimmanci a bar isassun kayan a gefe - tabbatar da zayyana sashin da babu inda za a sami isasshen kayan da za a yi lanƙwasawa.

Punching: Wannan aiki shine lokacin da aka danna gefuna na wani ɓangaren ƙarfe da aka hatimi don daidaitawa ko karya bursu; wannan yana ƙirƙirar gefuna masu santsi a cikin wuraren simintin gyare-gyare na ɓangaren lissafi; wannan kuma yana ƙara ƙarin ƙarfi ga wuraren da aka keɓance na ɓangaren, kuma Ana iya amfani da shi don guje wa sarrafa na biyu kamar ɓarna da niƙa.